Screen printing is the most common method used to print t-shirts. Your screen printer must first create a stencil on a piece of silk screened material before he can begin printing t-shirts. A regular stencil consists of two or more layers that are sandwiched together to allow for multiple prints (more colors).

Layers used in process

The first layer is called the positive and is usually made out of some type of thick photo emulsion. The next layer is called the squeegee or negative layer which is simply another sheet of silk screened material with one side covered in un-pigmented ink (black ink) and other side left clean.

This “blank” squeegee helps push the ink through the “stencil” creating your design. These two negative and positive silk screens are sandwiched together with a film of water in between them. The squeegee is pulled across the stencil forcing ink through the gaps of the stencil onto your shirt using heat, pressure and some sort of forced air to push it evenly out of the vat.

Effect of heat in screen printing machine

Heat presses have different temperature settings that affect how much heat is applied to the t-shirt during printing. Each screen printer has his own preferred press setting but basically, more heat is equal to less ink on your shirt while less heat means more ink on your shirt. So if you are looking for thicker lines on your print then apply more pressure when moving the squeegee while smoothing it out would require less pressure. To prevent your silk screened images from getting too hot, some screen printers will preheat their screens with the ink side up to avoid this problem.

Complete procedure

Most of the orders you receive from your customer will be 1 or 2 color prints on 100% cotton shirts that are preshrunk and double-needle stitched at a rate of about 180 per hour.

- The first step is to lay down a base coat which consists of printing the main ink color(s) over the entire shirt so if it’s a 4 color print you will have 4 different colors going down first before allowing time for drying.

- The next layer would consist of applying either a separate background color, second design element or outline around object in your design.

- When you are finished with all 4 colors, you will go back and outline your design to give it that extra pop.

Another common practice is the process of under-printing where a darker or pastel color is used underneath out design to create more depth in the print. There are many methods available for screen printing but this is just one of them.

How to use screen printing machine?

The following concepts have been brought up at multiple times during class.

- The first layer of a regular stencil consists of a negative material that holds an emulsion usually made up of photosensitive chemicals such as Magna-Emulsion. The next layer is called the squeegee or negative layer which consists of another sheet of silk screened material with one side covered in un-pigmented ink (black ink) and other side left clean. This “blank” squeegee helps push the ink through the “stencil” creating your design. These two negative and positive silk screens are sandwiched together with a film of water in between them that acts as a sort of sieve when printing. The squeegee is pulled across the stencil forcing ink through the gaps, resulting in your print.

- To prevent your silk screened images from getting too hot, some screen printers will preheat their screens with the ink/screen side down to avoid this problem.

- Generally speaking, more heat means less ink on your shirt and less heat means more ink on your shirt. You can control this with the pressure applied to the squeegee as you print. If you are looking for thicker lines on your print, then apply more pressure when moving the squeegee and if you want a smoother look, apply less.

- When printing shirts, it is common practice that each color gets laid down first before allowing time for drying. The next layer would consist of applying either a separate background color, second design element or outline around object in your design. Finally, after all desired colors have been added to fill up space/design elements, go back and outline your design to give it that extra pop.

Two important parts in printing machine

After deciding what type of silk screen you want to use, there are two important parts that must be done in order to make sure the stencil is ready for printing. These are given below.

- Once your silk screen has been “burned” (the emulsion has been exposed and hardened on the screen mesh), remove all of the remaining photo-emulsion with a specially formulated stripper. If you don’t do this step correctly, it will affect the quality of your print and most importantly your safety.

- After removing most (if not all) of the emulsion with a degreaser or flame, cover up any open areas in your stencil, otherwise ink can seep into these gaps and ruin your design when printed onto your shirt.

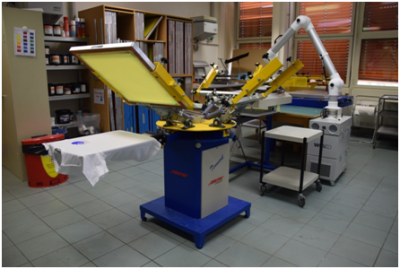

Screen printing machine as a small business

Screen printing machine can be used as a small business. Screen printing can cost $30,000 to $80,000. Now it depends on you that which machine you want to buy. A screen printing machine can be started from small machine and then you can make it bigger. This is total cost which you need to start the business including all the things. A screen printing machine can earn $100,000 per year. You just have to invest only one time than it will give monthly income.

Frequently asked questions

- Is the screen printing machine reliable?

Yes, of course it is reliable. And it is best to start a small business.

- For how much long does a machine work?

Once you purchased a good machine, it will work for many years.

- Can anyone start this business?

Yes, this is not difficult task. You just need experience to run the business.